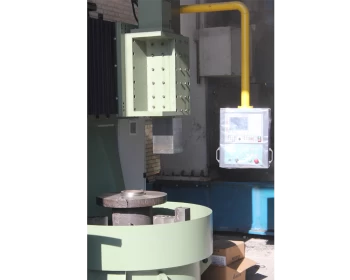

Download catalogue Cnc vertical lathe machine / carousel, live tool and power chuck (ZAGROS KARUSSELL)

K-1000, K-1100, K-1300, K-1600, K-2000

Cnc vertical lathe machine / carousel is produced for the machining of smooth, curved and spherical surfaces on the inner and outer surface of the part with a continuous operating accuracy of 0.02 mm. Also, this device has the capabilities of live tools such as nailing, drilling (0.5 degree angle accuracy) and grinding.

The production of products such as industrial pumps, large valves, railway industries, manufacturing parts for steel factories, oil and gas and petrochemical industries, parts for power plant and aviation industries, etc. are among the functions of this device.

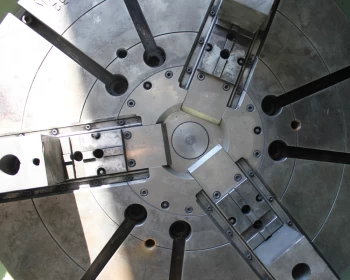

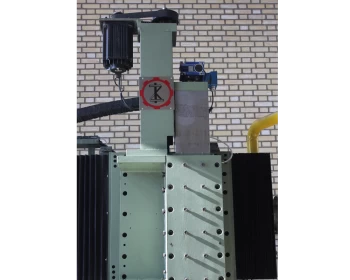

The table of these carousels is mounted on a large bearing with cross rollers (Cross Roller Bearing), which increases the strength and life of the device. Also, the horizontal axis (X) is implemented using a roller linear motion guide, which increases accuracy and reduces the vibration of the tool. The vertical axis guide (Z) is also a type of closed guide, which leads to strength and reducing the vibration of the device.

It should be noted that Cnc vertical lathe machine / carousel was designed and implemented by adapting the concept design of European-class carousels such as Pietro Carnaghi and improving and upgrading their technical features.